(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

- [Thông báo] Sử Dụng Địa Chỉ Hành Chính Mới Cho Giao/Nhận Hàng Hóa Từ 1/10/2025. Xem chi tiết.

[Notice] Update of Official Address for Delivery and Receipt of Goods from October 1, 2025. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng - Yêu Cầu Trả Phí Ship. Xem chi tiết

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more

Roughing End Mills (Carbide)

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

75 itemsMặt hàng

- Sort By

-

You can add up to 6 items per a category to the compare list.

YG 1

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 3 ~ 20 - - 6 ~ 20 3 ~ 5 - general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[◎] / Titanium[◎] - Plane / Side / Groove / Inclined Cuts TiAlN - Roughing From: 491,283 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Carbide Roughing End Mill, 4-Flute GM-4W

KABUSYUUKOUGU

GM Series end mill that has both high hardness and elastic modulus due to the use of carbide material and features the reasonable balance with the good cutting quality. It can extend the tool lifespan.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 6 ~ 20 16 ~ 45 - 6 ~ 20 4 50 ~ 100 general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[◎] Standard torsion (30-40°) Side / Groove TiAlN - Roughing From: 500,571 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

VAC Series Carbide Roughing End Mill

MISUMI

[Features]・High-speed rotation is possible by adopting a 45° helix. ・Using a fine pitch nick, the surface roughness after processing is also excellent. ・The conductivity is minimal. 《Additional machining》・Additional neck relief machining can be specified using MISUMI standard tools. ・No need to create drawings. You can order by simply specifying the dimensions using the model number. ・Available starting from 1 piece, ``just the quantity you need when you need it.'' ・Delivered on the 3rd day.

- Volume Discount

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 3 ~ 12 8 ~ 30 - 6 ~ 12 3 ~ 4 50 ~ 80 general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[◎] / Aluminum[○] / Copper[○] - Plane / Side / Groove / Plunging (Z feed) / Inclined Cuts - - Roughing Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

Roughing End Mill for Aluminum Machining AL-OCRL Type

DIJET

Ultrafine particle carbide alloy with excellent wear resistance ensures long tool life.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 6 ~ 30 26 ~ 82 - 6 ~ 25 3 75 ~ 180 Aluminum[◎] Standard torsion (30-40°) Side Non-Coated Sharp Edge Roughing From: 3,619,090 VND Days to Ship: Số ngày giao hàng: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

XAC series carbide roughing end mill, fine pitch / regular model

MISUMI

Strongly supports the cost reduction of roughing with the limited special price for standard sizes

- Volume Discount

- TiAlN

- General Steel

- R (Regular)

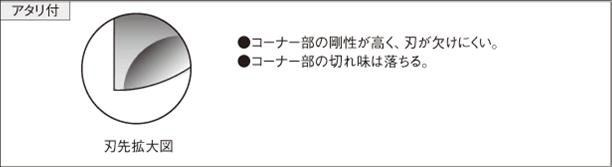

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 6 ~ 20 16 ~ 38 - 6 ~ 20 3 ~ 4 57 ~ 104 general steel[○] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Weak torsion (15 to 25˚) Plane / Side / Groove / Inclined Cuts TiAlN C plane Roughing From: 1,478,634 VND Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

TSC series carbide roughing end mill, fine pitch / long regular model

MISUMI

[Features]·Roughing end mill capable of coarse and middle to coarse machining with fine pitch nick·Long shank type ideal for deep cavity milling·It has coating with high oxidation resistance and high hardness, and achieves a long service lifespan. Effective in high-speed machining and dry machining as coating properties·Can be regrinded. Please refer to the page dedicated to "regrinding service" for usage procedures, range of services, prices, etc.

- Volume Discount

- TS

- General Steel

- R (Regular)

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 5 ~ 20 15 ~ 45 20 ~ 80 6 ~ 20 3 ~ 4 100 ~ 150 general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Weak torsion (15 to 25˚) Plane / Side / Groove / Inclined Cuts For High Hardness (Silicon Group) Micro R Roughing Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Carbide Roughing End Mill for Aluminum Machining, 3-Flute / Regular Model

MISUMI

Significantly reduces the roughing time of aluminum

- Volume Discount

- Non-Coated

- Aluminum

- 3 Flutes

- R (Regular)

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 5 ~ 20 15 ~ 45 20 ~ 70 6 ~ 20 3 57 ~ 100 Aluminum[◎] / Copper[○] Standard torsion (30-40°) Plane / Side / Groove / Inclined Cuts Non-Coated Micro R Roughing Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Router for CFRP Fine Pitch with Nick_DIA-BNC

OSG

A router that adopts a diamond coating with excellent abrasion resistance.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 4 ~ 12 12 ~ 36 - 4 ~ 12 6 ~ 14 62 ~ 94 Resin[◎] No torsion Plane / Side / Inclined Cuts Dia Coat With Lead Roughing From: 4,049,865 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Carbide 4-Flute Roughing/Finishing Coated End Mill

DYC

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 6 ~ 16 14 ~ 34 - 6 ~ 16 4 52 ~ 105 - - - - - Roughing From: 1,011,112 VND Days to Ship: Số ngày giao hàng: 7 Day(s)  7 Day(s)

7 Day(s)

-

You can add up to 6 items per a category to the compare list.

YG 1

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 3 ~ 25 8 ~ 50 - 6 ~ 25 3 ~ 5 50 ~ 100 general steel[○] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] Weak torsion (15 to 25˚) Plane / Side / Groove / Inclined Cuts TiAlN - Long-Neck Square From: 1,392,568 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

OptiMill® SCM410 Composite Material Router (Left Hand) Coarse Cross-Nick Router for Thick Sheets

MAPAL

[Features]· Optimal design for contour machining of composite materials such as CFRP, etc.· End mill specification with a base blade.· Cutting chips fall downward as it has a left-torsion specification.[Applications]· Work materials: Composites such as CFRP, etc.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 6 ~ 10 19 ~ 25 - 6 ~ 10 - 60 ~ 72 - - - - - Roughing From: 3,200,824 VND Days to Ship: Số ngày giao hàng: 9 Day(s) or more  9 Day(s) or more

9 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

MAPAL

[Features]· A new connection method "CFS" is adopted.· Guaranteed high runout accuracy of 5 μm or less.· Features simple operability and excellent stability.· Variable split greatly reduces cutting vibration (chatter).[Applications]· Work materials: Carbon steel, alloy steel, cast iron, stainless steel, light alloy.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 8 ~ 25 6 ~ 19 - 6 ~ 20 4 11 ~ 32 - - - - - Square From: 3,465,805 VND Days to Ship: Số ngày giao hàng: 9 Day(s) or more  9 Day(s) or more

9 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Diamond coated roughing rooter_DIA-REC

OSG

Processing application (processing shape) sideTool material: CarbideWork Material: Graphite/ResinCoating for non-ferrous metals (Diamond coating)Standard/Alteration category: Manufacturer's standard product

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 6 ~ 10 18 ~ 30 - 6 ~ 10 4 ~ 6 68 ~ 80 - - - Dia Coat - Square From: 4,806,328 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TSC series carbide roughing end mill, fine pitch / short model

MISUMI

[Features]·Roughing end mill capable of coarse and middle to coarse machining with fine pitch nick·It has coating with high oxidation resistance and high hardness, and achieves a long service lifespan. Effective in high-speed machining and dry machining as coating properties·Can be regrinded. Please refer to the page dedicated to "regrinding service" for usage procedures, range of services, prices, etc.

- Volume Discount

- TS

- General Steel

- 4 Flutes

- S (Short)

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 5 ~ 20 10 ~ 38 17 ~ 53 6 ~ 20 4 57 ~ 104 general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Weak torsion (15 to 25˚) Plane / Side / Inclined Cuts For High Hardness (Silicon Group) Micro R Roughing Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TSC series carbide roughing end mill, fine pitch / regular model

MISUMI

[Features]·Roughing end mill capable of coarse and middle to coarse machining with fine pitch nick·It has coating with high oxidation resistance and high hardness, and achieves a long service lifespan. Effective in high-speed machining and dry machining as coating properties·Can be regrinded. Please refer to the page dedicated to "regrinding service" for usage procedures, range of services, prices, etc.

- Volume Discount

- TS

- General Steel

- R (Regular)

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 3 ~ 20 15 ~ 45 20 ~ 70 6 ~ 20 3 ~ 4 60 ~ 130 general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Weak torsion (15 to 25˚) Plane / Side / Groove / Inclined Cuts For High Hardness (Silicon Group) Micro R Roughing Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TSC series carbide roughing end mill, fine pitch / long model

MISUMI

[Features]·Roughing end mill capable of coarse and middle to coarse machining with fine pitch nick·It has coating with high oxidation resistance and high hardness, and achieves a long service lifespan. Effective in high-speed machining and dry machining as coating properties·Can be regrinded. Please refer to the page dedicated to "regrinding service" for usage procedures, range of services, prices, etc.

- Volume Discount

- TS

- General Steel

- 4 Flutes

- L (Long)

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 6 ~ 20 25 ~ 65 30 ~ 90 6 ~ 20 4 100 ~ 150 general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Weak torsion (15 to 25˚) Plane / Side / Inclined Cuts For High Hardness (Silicon Group) Micro R Roughing Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TSC series carbide roughing end mill, 45° spiral / fine pitch / short model

MISUMI

[Features]·High-speed rotation processing is possible by adopting 45° helix angle·Roughing end mill capable of coarse and middle to coarse machining with fine pitch nick·It has coating with high oxidation resistance and high hardness, and achieves a long service lifespan. Effective in high-speed machining and dry machining as coating properties·Can be regrinded. Please refer to the page dedicated to "regrinding service" for usage procedures, range of services, prices, etc.

- Volume Discount

- TS

- General Steel

- S (Short)

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 5 ~ 20 10 ~ 38 17 ~ 60 6 ~ 20 3 ~ 4 60 ~ 110 general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Powerful Torsion (45°-60°) Plane / Side / Groove / Inclined Cuts For High Hardness (Silicon Group) C plane Roughing Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TSC series carbide roughing end mill, 45° spiral / fine pitch / regular model

MISUMI

[Features]·High-speed rotation processing is possible by adopting 45° helix angle·Roughing end mill capable of coarse and middle to coarse machining with fine pitch nick·It has coating with high oxidation resistance and high hardness, and achieves a long service lifespan. Effective in high-speed machining and dry machining as coating properties·Can be regrinded. Please refer to the page dedicated to "regrinding service" for usage procedures, range of services, prices, etc.

- Volume Discount

- TS

- General Steel

- R (Regular)

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 3 ~ 20 15 ~ 45 20 ~ 70 6 ~ 20 3 ~ 4 60 ~ 130 general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Powerful Torsion (45°-60°) Plane / Side / Groove / Inclined Cuts For High Hardness (Silicon Group) C plane Roughing Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TSC series carbide roughing end mill, 45° spiral / fine pitch / long model

MISUMI

[Features]·High-speed rotation processing is possible by adopting 45° helix angle·Roughing end mill capable of coarse and middle to coarse machining with fine pitch nick·It has coating with high oxidation resistance and high hardness, and achieves a long service lifespan. Effective in high-speed machining and dry machining as coating properties·Can be regrinded. Please refer to the page dedicated to "regrinding service" for usage procedures, range of services, prices, etc.

- Volume Discount

- TS

- General Steel

- L (Long)

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 6 ~ 20 25 ~ 65 30 ~ 90 6 ~ 20 3 ~ 4 100 ~ 150 general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Powerful Torsion (45°-60°) Plane / Side / Groove / Inclined Cuts For High Hardness (Silicon Group) C plane Roughing Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TS coated carbide roughing end mill, 45°spiral, fine pitch / long shank, regular model

MISUMI

[Features]·High-speed rotation processing is possible by adopting 45° helix angle·Roughing end mill capable of coarse and middle to coarse machining with fine pitch nick·Long shank type ideal for deep cavity milling·It has coating with high oxidation resistance and high hardness, and achieves a long service lifespan. Effective in high-speed machining and dry machining as coating properties

- Volume Discount

- TS

- General Steel

- R (Regular)

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 6 ~ 20 15 ~ 45 20 ~ 80 6 ~ 20 3 ~ 4 100 ~ 150 general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Aluminum[○] / Copper[○] Powerful Torsion (45°-60°) Plane / Side / Groove / Inclined Cuts For High Hardness (Silicon Group) C plane Roughing Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

DLC Coated Carbide Roughing End Mill for Aluminum Machining, 3-Flute / Regular Model

MISUMI

Popular DLC coated type of aluminum roughing

- Volume Discount

- DLC

- Aluminum

- 3 Flutes

- R (Regular)

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 5 ~ 20 15 ~ 45 20 ~ 70 6 ~ 20 3 57 ~ 100 Aluminum[◎] / Copper[○] / Resin[○] Standard torsion (30-40°) Plane / Side / Groove / Inclined Cuts DLC Micro R Roughing Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

NACHI(FUJIKOSHI)

Ideal for rough and medium finishing of materials from steel to stainless steel. High performance machining with BT30 machines is possible with little cutting resistance.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 6 ~ 20 13 ~ 38 - 6 ~ 20 4 50 ~ 100 general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[◎] / Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] Standard torsion (30-40°) Plane / Side / Groove / Inclined Cuts TiAlN With Lead Roughing From: 2,135,194 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

NACHI(FUJIKOSHI)

Capable of high-speed and high-efficiency roughing of materials from steel to stainless steel.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 6 ~ 20 13 ~ 38 - 6 ~ 20 4 50 ~ 100 general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[◎] / Cast Iron[◎] / Aluminum[○] / Titanium[○] / Copper[○] Standard torsion (30-40°) Plane / Side / Groove / Inclined Cuts TiAlN With Lead Roughing From: 2,136,177 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

GSX MILL Roughing 2.5D GSXRE-2.5D

NACHI(FUJIKOSHI)

Improved fracture resistance when used at high speeds for high efficiency. The GSX coating further improves heat resistance and abrasion resistance.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 4 ~ 20 10 ~ 50 - 6 ~ 20 4 45 ~ 100 general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[◎] / Cast Iron[◎] / Aluminum[○] / Titanium[○] / Copper[○] Standard torsion (30-40°) Plane / Side / Groove / Inclined Cuts For General Steels (AlCrN, etc.) With Lead Roughing From: 1,909,694 VND Days to Ship: Số ngày giao hàng: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Router for CFRP Herring Bone Type_DIA-HBC4

OSG

Standard in-stock item, sold by designated agencies.[Features]· A router that adopts a diamond coating with excellent abrasion resistance.· 4 base blades

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 6 ~ 10 15 ~ 25 - 6 ~ 10 4 65 ~ 75 - Standard torsion (30-40°) Plane / Side / Inclined Cuts Dia Coat With Lead Roughing From: 3,598,197 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

OSG

As the corrugated blade shape reduces cutting power, large cutting depth is possible. Also resilient to chatter, it is possible to improve the efficiency of roughing.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 7 ~ 25 16 ~ 45 - 8 ~ 25 4 ~ 6 60 ~ 120 general steel[○/◎] / Quenched and tempered steel[○/◎] / Stainless Steel[○/◎] / Cast Iron[○/◎] / Aluminum[○] / Titanium[○/◎] / Copper[○] Standard torsion (30-40°) / Powerful Torsion (45°-60°) Plane / Side / Inclined Cuts TiAlN C plane Roughing From: 3,367,395 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

FAGCNα, FA Coated Carbide Nα Nick

SANKO MFG

[Features]· Machining is possible with a wide range of materials, from raw materials to hardened steel.· New shape and new surface processing provide excellent chipping resistance and chip discharge.· A new standard considering usability of the blade length is adopted.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 3 ~ 25 10 ~ 62 22 ~ 57 3 ~ 25 3 ~ 4 50 ~ 140 general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[◎] / High Hardness Steel-HRC60[○] / Stainless Steel[◎] / Cast Iron[◎] / Titanium[○] Standard torsion (30-40°) Plane / Side / Groove / Inclined Cuts TiAlN C plane Roughing From: 2,261,626 VND Days to Ship: Số ngày giao hàng: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

SAGCVα SA Coated Carbide Victory α Nick

SANKO MFG

[Features]· Machining is possible with a wide range of materials, from raw materials to hardened steel.· Newly developed nick/cross-section shape provide excellent chipping resistance and chip discharge.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 5 ~ 20 13 ~ 38 18 6 ~ 20 4 50 ~ 110 general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[◎] / High Hardness Steel-HRC60[○] / Stainless Steel[◎] / Cast Iron[◎] / Titanium[○] Standard torsion (30-40°) Plane / Side / Groove / Inclined Cuts TiAlN C plane Roughing From: 2,167,653 VND Days to Ship: Số ngày giao hàng: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

SAGCα SA Coated Carbide α Nick

SANKO MFG

[Features]· With a unique roughing blade shape, heavy machining and high speed machining are possible

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 5 ~ 25 15 ~ 60 22 ~ 55 6 ~ 25 4 60 ~ 140 general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[◎] / High Hardness Steel-HRC60[○] / Stainless Steel[◎] / Cast Iron[○] / Titanium[○] Standard torsion (30-40°) Plane / Side / Groove / Inclined Cuts TiAlN C plane Roughing From: 2,481,550 VND Days to Ship: Số ngày giao hàng: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

ASAHI TOOLS

JIS usage classification symbol. Uses a tip material equivalent to M30 for roughing. Improves rough machining performance for nonferrous metals, cast iron, steel, etc.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 20 ~ 40 40 ~ 80 - 20 ~ 42 4 130 ~ 180 general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] Weak torsion (15 to 25˚) Side / Groove Non-Coated C plane Roughing From: 11,993,296 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

ASAHI TOOLS

JIS usage classification symbol. Uses a tip material equivalent to M30 for roughing. Improves rough machining performance for nonferrous metals, cast iron, steel, etc.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 20 ~ 40 60 ~ 120 - 20 ~ 42 4 150 ~ 220 general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] Weak torsion (15 to 25˚) Side / Groove Non-Coated C plane Roughing From: 14,491,345 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

ASAHI TOOLS

Ideal for side and groove machining of castings, carbon steel, stainless steel, and hard-to-cut material (up to HRC 65). Capable of radial cutting depth of 1/8 D in semi-finishing and finishing of high-hardness steel.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 3 ~ 20 3 ~ 80 - 6 ~ 20 4 ~ 8 45 ~ 140 general steel[○] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[◎] / High Hardness Steel-HRC60[◎] / Stainless Steel[◎] / Cast Iron[○] Standard torsion (30-40°) Side / Groove TiN With Lead Square From: 1,716,238 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

SPSRC4A SP Series Roughing End Mill 4-Flute OK Coat

OKAZAKI SEIKO

Its unique roughing shape and the effect of OK coating enable heavy cutting and high speed machining.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 5 ~ 25 12 ~ 45 - 4 ~ 25 4 50 ~ 120 general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[◎] / Cast Iron[◎] / Aluminum[○] / Titanium[○] Weak torsion (15 to 25˚) Plane / Side / Groove TiAlN C plane Roughing From: 1,396,658 VND Days to Ship: Số ngày giao hàng: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

SRE3 Roughing End Mill for Aluminum, 3-Flute, Non-Coated

OKAZAKI SEIKO

High-helix roughing end mill that demonstrates outstanding power for rough machining of aluminum materials.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 6 ~ 20 15 ~ 45 - 6 ~ 20 3 50 ~ 105 Aluminum[◎] / Copper[○] Standard torsion (30-40°) Plane / Side / Groove Non-Coated C plane Roughing From: 2,180,736 VND Days to Ship: Số ngày giao hàng: 10 Day(s) or more  10 Day(s) or more

10 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

SRE3D Roughing End Mill for Aluminum, 3-Flute, Pure DLC-Coated

OKAZAKI SEIKO

Pure DLC coating prevents chip welding, providing a surprisingly long lifespan.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 6 ~ 20 15 ~ 45 - 6 ~ 20 3 50 ~ 105 Aluminum[◎] / Copper[◎] Standard torsion (30-40°) Plane / Side / Groove DLC C plane Roughing From: 3,463,444 VND Days to Ship: Số ngày giao hàng: 10 Day(s) or more  10 Day(s) or more

10 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Roughing End Mill for Aluminum Machining AL-OCRS-LS Type

DIJET

Ultrafine particle carbide alloy with excellent wear resistance ensures long tool life.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 6 ~ 30 9 ~ 46 - 5 ~ 25 3 75 ~ 180 Aluminum[◎] Standard torsion (30-40°) Side Non-Coated Sharp Edge Roughing From: 2,598,355 VND Days to Ship: Số ngày giao hàng: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Roughing End Mill for Aluminum Machining AL-OCRS-XLS Type

DIJET

Ultrafine particle carbide alloy with excellent wear resistance ensures long tool life.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 6 ~ 22 9 ~ 33 - 5 ~ 20 3 100 ~ 250 Aluminum[◎] Standard torsion (30-40°) Side Non-Coated Sharp Edge Roughing From: 2,834,615 VND Days to Ship: Số ngày giao hàng: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Roughing End Mill for Aluminum Machining AL-OCRS Type

DIJET

Ultrafine particle carbide alloy with excellent wear resistance ensures long tool life.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 3 ~ 30 6 ~ 51 - 4 ~ 25 3 50 ~ 140 Aluminum[◎] Standard torsion (30-40°) Side / Groove Non-Coated Sharp Edge Roughing From: 2,180,023 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

DIJET

Ultrafine particle carbide alloy with excellent wear resistance ensures long tool life.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 4 ~ 25 8 ~ 50 - 6 ~ 25 3 ~ 4 55 ~ 130 general steel[◎] / Quenched and tempered steel[◎] / Cast Iron[◎] Weak torsion (15 to 25˚) Side / Groove TiAlN - Roughing From: 4,788,828 VND Days to Ship: Số ngày giao hàng: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Roughing End Mill Regular 3-Flute 3127

GUHRING

Roughing endmill dedicated for aluminum.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 6 ~ 25 - - 6 ~ 25 3 57 ~ 121 - Standard torsion (30-40°) - - - Roughing From: 1,725,651 VND Days to Ship: Số ngày giao hàng: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Roughing End Mill Regular 4-Flute 3723

GUHRING

Supports a wide range of high-speed rough machining from general steel to stainless steel.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 6 ~ 25 - - 6 ~ 25 4 57 ~ 121 - Standard torsion (30-40°) - - - Roughing From: 2,545,983 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Roughing End Mill Regular 4-Flute for High Hardness Steel 3682

GUHRING

Capable of rough machining of hardened materials up to hardness of 56 HRC.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 6 ~ 20 - - 6 ~ 20 4 57 ~ 104 - Weak torsion (15 to 25˚) - - - Roughing From: 3,463,130 VND Days to Ship: Số ngày giao hàng: 24 Day(s) or more  24 Day(s) or more

24 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

High Chip Flow Performance Wave Shaped Blade for Ruffing 3RDSM, 4RDSM, 5RDSM (Medium)

KYOCERA

·Roughing corrugated cutting edge·For coarse machining, the repertoire includes 3, 4, and 5 flutes.The sine curve cutting edge reduces cutting force.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 5 ~ 6 13 - 6 3 57 general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[○] / Cast Iron[◎] Weak torsion (15 to 25˚) Plane / Side / Groove TiAlN - Roughing From: 1,842,672 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

CoroMill Plura, Carbide Shoulder Grinding End Mill

SANDVIK

Unique shape exhibits high performance

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 6 ~ 16 13 ~ 20 63 6 ~ 16 3 57 ~ 115 Aluminum[○] / Copper[○] Standard torsion (30-40°) Groove Non-Coated - Roughing From: 2,471,728 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Roughing End Mill for Aluminum Processing, Regular Flute Length with Chamfered Corner AL-OCRS

DIJET

Ultrafine particle carbide alloy with excellent wear resistance ensures long tool life.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 6 ~ 25 13 ~ 51 - 6 ~ 25 3 55 ~ 130 Aluminum[◎] Standard torsion (30-40°) Side / Groove Non-Coated Sharp Edge Roughing From: 3,328,645 VND Days to Ship: Số ngày giao hàng: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| CADCAD |

| From |

| Days to ShipSố ngày giao hàng |

| SpecificationsĐặc điểm kĩ thuật |

| Blade diameter (D)(φ) |

| Blade length (ℓ)(mm) |

| Underneck length (ℓ1)(mm) |

| Shank diameter (d)(mm) |

| Number of flutes(sheet) |

| Overall Length (L)(mm) |

| work material |

| Torsion Angle (θ) |

| Machining Application |

| Coating |

| Blade tip shape |

| Type |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | YG 1 | KABUSYUUKOUGU | MISUMI | DIJET | MISUMI | MISUMI | MISUMI | OSG | DYC | YG 1 | MAPAL | MAPAL | OSG | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | NACHI(FUJIKOSHI) | NACHI(FUJIKOSHI) | NACHI(FUJIKOSHI) | OSG | OSG | SANKO MFG | SANKO MFG | SANKO MFG | ASAHI TOOLS | ASAHI TOOLS | ASAHI TOOLS | OKAZAKI SEIKO | OKAZAKI SEIKO | OKAZAKI SEIKO | DIJET | DIJET | DIJET | DIJET | GUHRING | GUHRING | GUHRING | KYOCERA | SANDVIK | DIJET |

| Product SeriesDòng sản phẩm | XAC series carbide roughing end mill, fine pitch / regular model | TSC series carbide roughing end mill, fine pitch / long regular model | Carbide Roughing End Mill for Aluminum Machining, 3-Flute / Regular Model | OptiMill® SCM410 Composite Material Router (Left Hand) Coarse Cross-Nick Router for Thick Sheets | TSC series carbide roughing end mill, fine pitch / short model | TSC series carbide roughing end mill, fine pitch / regular model | TSC series carbide roughing end mill, fine pitch / long model | TSC series carbide roughing end mill, 45° spiral / fine pitch / short model | TSC series carbide roughing end mill, 45° spiral / fine pitch / regular model | TSC series carbide roughing end mill, 45° spiral / fine pitch / long model | TS coated carbide roughing end mill, 45°spiral, fine pitch / long shank, regular model | DLC Coated Carbide Roughing End Mill for Aluminum Machining, 3-Flute / Regular Model | SRE3D Roughing End Mill for Aluminum, 3-Flute, Pure DLC-Coated | Roughing End Mill Regular 4-Flute for High Hardness Steel 3682 | High Chip Flow Performance Wave Shaped Blade for Ruffing 3RDSM, 4RDSM, 5RDSM (Medium) | Roughing End Mill for Aluminum Processing, Regular Flute Length with Chamfered Corner AL-OCRS | |||||||||||||||||||||||||||||

| CADCAD |

|

|

|

| |||||||||||||||||||||||||||||||||||||||||

| From | 491,283 VND | 500,571 VND | 3,619,090 VND | 1,478,634 VND | 4,049,865 VND | 1,011,112 VND | 1,392,568 VND | 3,200,824 VND | 3,465,805 VND | 4,806,328 VND | 2,135,194 VND | 2,136,177 VND | 1,909,694 VND | 3,598,197 VND | 3,367,395 VND | 2,261,626 VND | 2,167,653 VND | 2,481,550 VND | 11,993,296 VND | 14,491,345 VND | 1,716,238 VND | 1,396,658 VND | 2,180,736 VND | 3,463,444 VND | 2,598,355 VND | 2,834,615 VND | 2,180,023 VND | 4,788,828 VND | 1,725,651 VND | 2,545,983 VND | 3,463,130 VND | 1,842,672 VND | 2,471,728 VND | 3,328,645 VND | |||||||||||

| Days to ShipSố ngày giao hàng | 4 Day(s) or more | 4 Day(s) or more | Same day or more | 7 Day(s) or more | Same day or more | 4 Day(s) or more | 4 Day(s) or more | 6 Day(s) or more | 7 Day(s) | 4 Day(s) or more | 9 Day(s) or more | 9 Day(s) or more | 6 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 5 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 8 Day(s) or more | 8 Day(s) or more | 8 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 7 Day(s) or more | 10 Day(s) or more | 10 Day(s) or more | 7 Day(s) or more | 8 Day(s) or more | 6 Day(s) or more | 8 Day(s) or more | 8 Day(s) or more | 6 Day(s) or more | 24 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 8 Day(s) or more |

| SpecificationsĐặc điểm kĩ thuật |

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||||||||||||||||||||||

| Blade diameter (D)(φ) | 3 ~ 20 | 6 ~ 20 | 3 ~ 12 | 6 ~ 30 | 6 ~ 20 | 5 ~ 20 | 5 ~ 20 | 4 ~ 12 | 6 ~ 16 | 3 ~ 25 | 6 ~ 10 | 8 ~ 25 | 6 ~ 10 | 5 ~ 20 | 3 ~ 20 | 6 ~ 20 | 5 ~ 20 | 3 ~ 20 | 6 ~ 20 | 6 ~ 20 | 5 ~ 20 | 6 ~ 20 | 6 ~ 20 | 4 ~ 20 | 6 ~ 10 | 7 ~ 25 | 3 ~ 25 | 5 ~ 20 | 5 ~ 25 | 20 ~ 40 | 20 ~ 40 | 3 ~ 20 | 5 ~ 25 | 6 ~ 20 | 6 ~ 20 | 6 ~ 30 | 6 ~ 22 | 3 ~ 30 | 4 ~ 25 | 6 ~ 25 | 6 ~ 25 | 6 ~ 20 | 5 ~ 6 | 6 ~ 16 | 6 ~ 25 |

| Blade length (ℓ)(mm) | - | 16 ~ 45 | 8 ~ 30 | 26 ~ 82 | 16 ~ 38 | 15 ~ 45 | 15 ~ 45 | 12 ~ 36 | 14 ~ 34 | 8 ~ 50 | 19 ~ 25 | 6 ~ 19 | 18 ~ 30 | 10 ~ 38 | 15 ~ 45 | 25 ~ 65 | 10 ~ 38 | 15 ~ 45 | 25 ~ 65 | 15 ~ 45 | 15 ~ 45 | 13 ~ 38 | 13 ~ 38 | 10 ~ 50 | 15 ~ 25 | 16 ~ 45 | 10 ~ 62 | 13 ~ 38 | 15 ~ 60 | 40 ~ 80 | 60 ~ 120 | 3 ~ 80 | 12 ~ 45 | 15 ~ 45 | 15 ~ 45 | 9 ~ 46 | 9 ~ 33 | 6 ~ 51 | 8 ~ 50 | - | - | - | 13 | 13 ~ 20 | 13 ~ 51 |

| Underneck length (ℓ1)(mm) | - | - | - | - | - | 20 ~ 80 | 20 ~ 70 | - | - | - | - | - | - | 17 ~ 53 | 20 ~ 70 | 30 ~ 90 | 17 ~ 60 | 20 ~ 70 | 30 ~ 90 | 20 ~ 80 | 20 ~ 70 | - | - | - | - | - | 22 ~ 57 | 18 | 22 ~ 55 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 63 | - |

| Shank diameter (d)(mm) | 6 ~ 20 | 6 ~ 20 | 6 ~ 12 | 6 ~ 25 | 6 ~ 20 | 6 ~ 20 | 6 ~ 20 | 4 ~ 12 | 6 ~ 16 | 6 ~ 25 | 6 ~ 10 | 6 ~ 20 | 6 ~ 10 | 6 ~ 20 | 6 ~ 20 | 6 ~ 20 | 6 ~ 20 | 6 ~ 20 | 6 ~ 20 | 6 ~ 20 | 6 ~ 20 | 6 ~ 20 | 6 ~ 20 | 6 ~ 20 | 6 ~ 10 | 8 ~ 25 | 3 ~ 25 | 6 ~ 20 | 6 ~ 25 | 20 ~ 42 | 20 ~ 42 | 6 ~ 20 | 4 ~ 25 | 6 ~ 20 | 6 ~ 20 | 5 ~ 25 | 5 ~ 20 | 4 ~ 25 | 6 ~ 25 | 6 ~ 25 | 6 ~ 25 | 6 ~ 20 | 6 | 6 ~ 16 | 6 ~ 25 |

| Number of flutes(sheet) | 3 ~ 5 | 4 | 3 ~ 4 | 3 | 3 ~ 4 | 3 ~ 4 | 3 | 6 ~ 14 | 4 | 3 ~ 5 | - | 4 | 4 ~ 6 | 4 | 3 ~ 4 | 4 | 3 ~ 4 | 3 ~ 4 | 3 ~ 4 | 3 ~ 4 | 3 | 4 | 4 | 4 | 4 | 4 ~ 6 | 3 ~ 4 | 4 | 4 | 4 | 4 | 4 ~ 8 | 4 | 3 | 3 | 3 | 3 | 3 | 3 ~ 4 | 3 | 4 | 4 | 3 | 3 | 3 |

| Overall Length (L)(mm) | - | 50 ~ 100 | 50 ~ 80 | 75 ~ 180 | 57 ~ 104 | 100 ~ 150 | 57 ~ 100 | 62 ~ 94 | 52 ~ 105 | 50 ~ 100 | 60 ~ 72 | 11 ~ 32 | 68 ~ 80 | 57 ~ 104 | 60 ~ 130 | 100 ~ 150 | 60 ~ 110 | 60 ~ 130 | 100 ~ 150 | 100 ~ 150 | 57 ~ 100 | 50 ~ 100 | 50 ~ 100 | 45 ~ 100 | 65 ~ 75 | 60 ~ 120 | 50 ~ 140 | 50 ~ 110 | 60 ~ 140 | 130 ~ 180 | 150 ~ 220 | 45 ~ 140 | 50 ~ 120 | 50 ~ 105 | 50 ~ 105 | 75 ~ 180 | 100 ~ 250 | 50 ~ 140 | 55 ~ 130 | 57 ~ 121 | 57 ~ 121 | 57 ~ 104 | 57 | 57 ~ 115 | 55 ~ 130 |

| work material | general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[◎] / Titanium[◎] | general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[◎] | general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[◎] / Aluminum[○] / Copper[○] | Aluminum[◎] | general steel[○] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | Aluminum[◎] / Copper[○] | Resin[◎] | - | general steel[○] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] | - | - | - | general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Aluminum[○] / Copper[○] | Aluminum[◎] / Copper[○] / Resin[○] | general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[◎] / Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] | general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[◎] / Cast Iron[◎] / Aluminum[○] / Titanium[○] / Copper[○] | general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[◎] / Cast Iron[◎] / Aluminum[○] / Titanium[○] / Copper[○] | - | general steel[○/◎] / Quenched and tempered steel[○/◎] / Stainless Steel[○/◎] / Cast Iron[○/◎] / Aluminum[○] / Titanium[○/◎] / Copper[○] | general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[◎] / High Hardness Steel-HRC60[○] / Stainless Steel[◎] / Cast Iron[◎] / Titanium[○] | general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[◎] / High Hardness Steel-HRC60[○] / Stainless Steel[◎] / Cast Iron[◎] / Titanium[○] | general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[◎] / High Hardness Steel-HRC60[○] / Stainless Steel[◎] / Cast Iron[○] / Titanium[○] | general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[◎] / High Hardness Steel-HRC60[◎] / Stainless Steel[◎] / Cast Iron[○] | general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[◎] / Cast Iron[◎] / Aluminum[○] / Titanium[○] | Aluminum[◎] / Copper[○] | Aluminum[◎] / Copper[◎] | Aluminum[◎] | Aluminum[◎] | Aluminum[◎] | general steel[◎] / Quenched and tempered steel[◎] / Cast Iron[◎] | - | - | - | general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[○] / Cast Iron[◎] | Aluminum[○] / Copper[○] | Aluminum[◎] |

| Torsion Angle (θ) | - | Standard torsion (30-40°) | - | Standard torsion (30-40°) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Standard torsion (30-40°) | No torsion | - | Weak torsion (15 to 25˚) | - | - | - | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Powerful Torsion (45°-60°) | Powerful Torsion (45°-60°) | Powerful Torsion (45°-60°) | Powerful Torsion (45°-60°) | Standard torsion (30-40°) | Standard torsion (30-40°) | Standard torsion (30-40°) | Standard torsion (30-40°) | Standard torsion (30-40°) | Standard torsion (30-40°) / Powerful Torsion (45°-60°) | Standard torsion (30-40°) | Standard torsion (30-40°) | Standard torsion (30-40°) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Standard torsion (30-40°) | Weak torsion (15 to 25˚) | Standard torsion (30-40°) | Standard torsion (30-40°) | Standard torsion (30-40°) | Standard torsion (30-40°) | Standard torsion (30-40°) | Weak torsion (15 to 25˚) | Standard torsion (30-40°) | Standard torsion (30-40°) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Standard torsion (30-40°) | Standard torsion (30-40°) |

| Machining Application | Plane / Side / Groove / Inclined Cuts | Side / Groove | Plane / Side / Groove / Plunging (Z feed) / Inclined Cuts | Side | Plane / Side / Groove / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Inclined Cuts | - | Plane / Side / Groove / Inclined Cuts | - | - | - | Plane / Side / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Inclined Cuts | Plane / Side / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Side / Groove | Side / Groove | Side / Groove | Plane / Side / Groove | Plane / Side / Groove | Plane / Side / Groove | Side | Side | Side / Groove | Side / Groove | - | - | - | Plane / Side / Groove | Groove | Side / Groove |

| Coating | TiAlN | TiAlN | - | Non-Coated | TiAlN | For High Hardness (Silicon Group) | Non-Coated | Dia Coat | - | TiAlN | - | - | Dia Coat | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | DLC | TiAlN | TiAlN | For General Steels (AlCrN, etc.) | Dia Coat | TiAlN | TiAlN | TiAlN | TiAlN | Non-Coated | Non-Coated | TiN | TiAlN | Non-Coated | DLC | Non-Coated | Non-Coated | Non-Coated | TiAlN | - | - | - | TiAlN | Non-Coated | Non-Coated |

| Blade tip shape | - | - | - | Sharp Edge | C plane | Micro R | Micro R | With Lead | - | - | - | - | - | Micro R | Micro R | Micro R | C plane | C plane | C plane | C plane | Micro R | With Lead | With Lead | With Lead | With Lead | C plane | C plane | C plane | C plane | C plane | C plane | With Lead | C plane | C plane | C plane | Sharp Edge | Sharp Edge | Sharp Edge | - | - | - | - | - | - | Sharp Edge |

| Type | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing | Long-Neck Square | Roughing | Square | Square | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing | Square | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing | Roughing |

Loading...Tải…

ConfigureTạo

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Blade diameter (D)(φ)

-

Blade length (ℓ)(mm)

-

3

-

4

-

5

-

6

-

7~7.5

- 7

- 7.5

-

8

-

9

-

10

-

11

-

12~12.5

- 12

- 12.5

-

13

-

14

-

15

-

16

-

17~17.5

- 17

- 17.5

-

18

-

19

-

20

-

21

-

22~22.5

- 22

- 22.5

-

23

-

24

-

25~25.4

- 25

- 25.4

-

26

-

27~27.5

- 27

- 27.5

-

28~28.58

- 28

- 28.58

-

30

-

31

-

32

-

33

-

34

-

35

-

36

-

37

-

38

-

40

-

42

-

44

-

45

-

46

-

47

-

48

-

50

-

51

-

52

-

54

-

55

-

56

-

60

-

62

-

63

-

64

-

65

-

67

-

70

-

72

-

75

-

78

-

80

-

82

-

90

-

100

-

120

-

-

Underneck length (ℓ1)(mm)

-

Shank diameter (d)(mm)

-

Number of flutes(sheet)

-

Overall Length (L)(mm)

-

work material

-

Torsion Angle (θ)

-

Machining Application

-

Coating

-

Blade tip shape

-

Type

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy