(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

- [Thông báo] Sử Dụng Địa Chỉ Hành Chính Mới Cho Giao/Nhận Hàng Hóa Từ 1/10/2025. Xem chi tiết.

[Notice] Update of Official Address for Delivery and Receipt of Goods from October 1, 2025. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng - Yêu Cầu Trả Phí Ship. Xem chi tiết

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Table O.D.(Ø)

-

Motor, Motor Characteristics

- 2-Phase Stepping Motor - Standard

-

Type

- Motorized Rotary Stage

-

Load Capacity (Range)(N)

- 5~30

- 30.1~50

- 100.1~

-

Material

- Aluminum(Aluminum Alloy)

-

Guide

- Deep Groove Ball Bearing

-

Minimum Resolution (Angle)(deg)

-

Stroke (θ Angle)(deg)

- 360

-

Surface Treatment

- Black Anodize

-

Through Hole (Table Center Hole)

- Provided

-

Load Capacity(N)

-

Part Number

-

Driver

- A

- N

-

Cable

- 2

- 4

-

type

- E-RMPG

-

CADCAD

- 2D

- 3D

Days to ShipSố ngày giao hàng

-

- Alltất cả các

- 8 Day(s) or Less

- 19 Day(s) or Less

Specify AlterationsChỉ định thay đổi

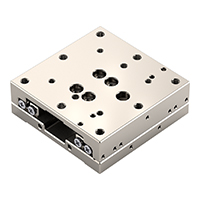

Motorized Rotary Stages Worm Gear Type, Position Repeatability ±0.08°

- Volume Discount

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

Material: Aluminum Alloy of Rotary

Material: Aluminum Alloy of Rotary Surface Treatment: Black Anodized

Surface Treatment: Black Anodized| Part Number |  Driver Driver |  Cable Cable | Mechanical Specification | Accuracy Specification | Sensor | ||||||||

Type Type |  No. No. | Stage Surface (mm) | Travel Distance (°) | Load Capacity (N) | Weight (kg) | Maximum Speed (°/sec) | One-Way Positioning Accuracy | Repetitive Positioning Accuracy | Parallelism (μm) | Limit Sensor | Origin Sensor (ORG1) | ||

| E-RMPG | 40 | A | φ39 | 360 | 29.4 | 0.5 | 25 | Within 0.15° | Within ±0.08° | Within 50 | Not Provided | Provided | |

| 60 | 2 (2m cable) | φ60 | 39.2 | 0.9 | 15 | ||||||||

| 80 | φ79 | 39.2 | 1.1 | 15 | |||||||||

| 100 | 4 (4m cable) | φ99 | 196 | 1.9 | 25 | ||||||||

| 120 | φ119 | 196 | 2.2 | 25 | |||||||||

Driver: Driver model used in this series: E-DR42B.

Driver: Driver model used in this series: E-DR42B.| No. | 40 | 60 | 80 | 100 | 120 | |

| Reduction Ratio | 1/120 | 1/180 | 1/180 | 1/120 | 1/120 | |

| Guide Rail | Deep Groove Ball Bearing | |||||

| Motor | Shape | 2-Phase Standard Stepper Motor 1.3 A/Phase | 2-Phase Standard Stepper Motor 1.3 A/Phase | 2-Phase High Torque Stepper Motor 1.3 A/Phase | 2-Phase Standard Stepper Motor 2.0 A/Phase | 2-Phase Standard Stepper Motor 2.0 A/Phase |

| Step Angle | 1.8° | |||||

| Resolution (Pulse) Full | ≒0.015° | ≒0.01 | ≒0.01° | ≒0.015° | ≒0.015° | |

| Driver | Power Voltage | DC12 to 50 V | ||||

| Output Current | 0.1 to 2.2 A | |||||

| Pulse Signal Voltage | 5 to 24 V | |||||

| Number of Subdivisions | 200 to 51200 | |||||

| Connector | Part Number | HR10A-10R-12P (Hirose) | ||||

| Receiving side part number | HR10A-10P-12S (Hirose) | |||||

| Sensor Substrate | Limit Sensor | Not Provided | ||||

| Origin Sensor | Provided | |||||

| Power Voltage | 24 V DC±10% | |||||

| Sensor Type | Miniature Photo Sensor RPI-0125 (ROHM) | |||||

| Control Output | NPN Open Collector Output | |||||

| Output Logic | During detection (shading): Output transistor OFF (non-conducting) | |||||

.jpg)

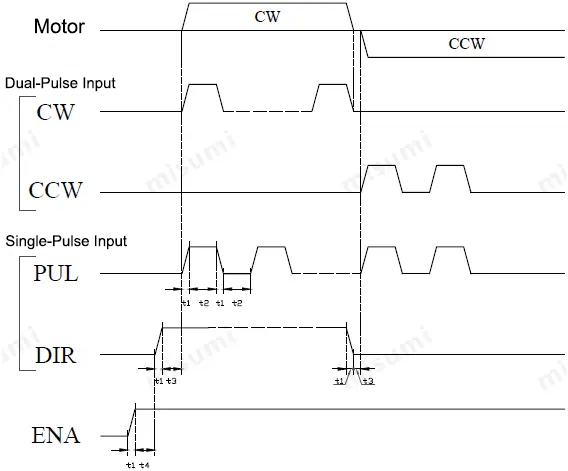

■ Timing Diagram

t1<0.1us t2 ≥ 0.9us t3 ≥ 10us

t4: ENA (Enable signal) t4 should be set high at least 10µs before DIR. In general, it is recommended to leave ENA+ and ENA- unconnected.

Product Features

Usage Method

Precautions

Operating environment: 10 to 50°C, 20 to 70%RH (non-condensing)

Recommended environment: 22±5°C, 20 to 70%RH (non-condensing)

Please avoid using the slide table in the following environments

(1) Dusty environments (especially metal powder)

(2) Environments with direct sunlight or heat radiation

(3) Near fire sources

(4) Environments with corrosive or flammable gases

(5) Environments with splashing water or oil

(6) Environments with strong vibration or impact

(7) Environments with organic solvents or high salt content

■About Slide Table Maintenance

There is no unified regular maintenance standard due to differences in grease types and usage environments. Depending on the drive conditions and the type of guide rail, please be sure to check the grease at least once a month.

Application Industries of Rotary

| Electronics/Home Appliance | Automotive | Medical | ||

|  |  | ||

| Smart phone | Semiconductor | Lithium battery | ||

|  |  |

Related Products of Rotary

| Economy series X-Axis Motorized Positioning Rotary | Economy series XY-Axis Motorized Positioning Rotary | Economy series Z-Axis Motorized Positioning Rotary |

|  |  |

| Representative model of Rotary: C-XMBS420-L-A-2 | Representative model of Rotary: C-XYMBS420-L-A-2 | Representative model of Rotary: C-ZMBS420-L-A-2 |

Related Documents

Compatible drivers support dual-pulse and pulse + direction control. For installation dimensions and user manual, please refer to: E-DR42B.

| Electronics/home appliance | Automotive | Medical |

Part Number

- Incomplete part number.

Please use left hand selections to complete a part number.Incomplete part number.

Please use left hand selections to complete a part number.

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to ShipSố ngày giao hàng | Table O.D. (Ø) | Motor, Motor Characteristics | Type | Load Capacity (Range) (N) | Material | Guide | Minimum Resolution (Angle) (deg) | Stroke (θ Angle) (deg) | Surface Treatment | Through Hole (Table Center Hole) | Load Capacity (N) | Max. Speed (mm/sec) | Table Parallelism (µm) | Part Number | Driver | Cable |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

10,435,904 VND | 1 Piece(s) | Available | 19 Day(s) | 40 | 2-Phase Stepping Motor - Standard | Motorized Rotary Stage | 5~30 | Aluminum(Aluminum Alloy) | Deep Groove Ball Bearing | 0.015 | 360 | Black Anodize | Provided | 29.4 | 25 | 50 or less | E-RMPG40 | A | 2 | |

10,672,917 VND | 1 Piece(s) | Available | 19 Day(s) | 40 | 2-Phase Stepping Motor - Standard | Motorized Rotary Stage | 5~30 | Aluminum(Aluminum Alloy) | Deep Groove Ball Bearing | 0.015 | 360 | Black Anodize | Provided | 29.4 | 25 | 50 or less | E-RMPG40 | A | 4 | |

9,765,228 VND | 1 Piece(s) | Available | 19 Day(s) | 39 | - | - | - | - | - | - | - | - | - | - | - | - | - | N | 2 | |

10,002,523 VND | 1 Piece(s) | Available | 19 Day(s) | 39 | - | - | - | - | - | - | - | - | - | - | - | - | - | N | 4 | |

10,814,117 VND | 1 Piece(s) | Available | 8 Day(s) | 60 | 2-Phase Stepping Motor - Standard | Motorized Rotary Stage | 30.1~50 | Aluminum(Aluminum Alloy) | Deep Groove Ball Bearing | 0.01 | 360 | Black Anodize | Provided | 39.2 | 15 | 50 or less | E-RMPG60 | A | 2 | |

10,640,772 VND | 1 Piece(s) | Available | 19 Day(s) | 60 | 2-Phase Stepping Motor - Standard | Motorized Rotary Stage | 30.1~50 | Aluminum(Aluminum Alloy) | Deep Groove Ball Bearing | 0.01 | 360 | Black Anodize | Provided | 39.2 | 15 | 50 or less | E-RMPG60 | A | 4 | |

9,733,045 VND | 1 Piece(s) | Available | 19 Day(s) | 60 | - | - | - | - | - | - | - | - | - | - | - | - | - | N | 2 | |

9,970,341 VND | 1 Piece(s) | Available | 19 Day(s) | 60 | - | - | - | - | - | - | - | - | - | - | - | - | - | N | 4 | |

16,424,957 VND | 1 Piece(s) | Available | 19 Day(s) | 79 | 2-Phase Stepping Motor - Standard | Motorized Rotary Stage | 30.1~50 | Aluminum(Aluminum Alloy) | Deep Groove Ball Bearing | 0.01 | 360 | Black Anodize | Provided | 39.2 | 15 | 50 or less | E-RMPG80 | A | 2 | |

16,661,970 VND | 1 Piece(s) | Available | 19 Day(s) | 79 | 2-Phase Stepping Motor - Standard | Motorized Rotary Stage | 30.1~50 | Aluminum(Aluminum Alloy) | Deep Groove Ball Bearing | 0.01 | 360 | Black Anodize | Provided | 39.2 | 15 | 50 or less | E-RMPG80 | A | 4 | |

15,761,424 VND | 1 Piece(s) | Available | 19 Day(s) | 79 | - | - | - | - | - | - | - | - | - | - | - | - | - | N | 2 | |

15,998,720 VND | 1 Piece(s) | Available | 19 Day(s) | 79 | - | - | - | - | - | - | - | - | - | - | - | - | - | N | 4 | |

17,928,739 VND | 1 Piece(s) | Available | 19 Day(s) | 99 | 2-Phase Stepping Motor - Standard | Motorized Rotary Stage | 100.1~ | Aluminum(Aluminum Alloy) | Deep Groove Ball Bearing | 0.015 | 360 | Black Anodize | Provided | 196 | 25 | 50 or less | E-RMPG100 | A | 2 | |

18,165,752 VND | 1 Piece(s) | Available | 19 Day(s) | 99 | 2-Phase Stepping Motor - Standard | Motorized Rotary Stage | 100.1~ | Aluminum(Aluminum Alloy) | Deep Groove Ball Bearing | 0.015 | 360 | Black Anodize | Provided | 196 | 25 | 50 or less | E-RMPG100 | A | 4 | |

17,267,000 VND | 1 Piece(s) | Available | 19 Day(s) | 99 | - | - | - | - | - | - | - | - | - | - | - | - | - | N | 2 | |

17,504,295 VND | 1 Piece(s) | Available | 19 Day(s) | 99 | - | - | - | - | - | - | - | - | - | - | - | - | - | N | 4 | |

19,965,631 VND | 1 Piece(s) | Available | 19 Day(s) | 119 | 2-Phase Stepping Motor - Standard | Motorized Rotary Stage | 100.1~ | Aluminum(Aluminum Alloy) | Deep Groove Ball Bearing | 0.015 | 360 | Black Anodize | Provided | 196 | 25 | 50 or less | E-RMPG120 | A | 2 | |

20,202,644 VND | 1 Piece(s) | Available | 19 Day(s) | 119 | 2-Phase Stepping Motor - Standard | Motorized Rotary Stage | 100.1~ | Aluminum(Aluminum Alloy) | Deep Groove Ball Bearing | 0.015 | 360 | Black Anodize | Provided | 196 | 25 | 50 or less | E-RMPG120 | A | 4 | |

19,306,322 VND | 1 Piece(s) | Available | 19 Day(s) | 119 | - | - | - | - | - | - | - | - | - | - | - | - | - | N | 2 | |

19,543,617 VND | 1 Piece(s) | Available | 19 Day(s) | 119 | - | - | - | - | - | - | - | - | - | - | - | - | - | N | 4 |

Loading...Tải…

Basic InformationThông tin cơ bản

| Table Feeding Method | Ball Screw |

|---|

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer toCác thông số kỹ thuật và kích thước của mã sản phẩm có thể không được bao phủ đầy đủ. Để biết chi tiết chính xác, hãy tham khảo manufacturer catalogsdanh mục nhà sản xuất ..

Frequently asked question (FAQ)FAQ

- Question:Question: Can the MISUMI electric slide table be used directly after purchase? Are any additional accessories required for actual operation?

- Answer:Answer: In addition to purchasing the MISUMI automatic slide table (which already includes the motor driver and a 2-meter cable), Additionally, customers need to prepare a 24 V power supply and control unit by themselves.

- Question:Question: Why does my slide table only operate in one direction?

-

Answer:Answer:

1. The direction signal may be too weak, the wiring may be reversed, or the signal voltage may be too high and has burned out the internal current-limiting resistor.

2. The pulse mode does not match; the signal mode must be consistent with the driver settings, otherwise the slide table will not rotate or will only move in one direction. - Question:Question: What is the accuracy of the stepper motor? Does the error accumulate?

- Answer:Answer: The accuracy of a typical stepper motor is 3–5% of the step angle. The deviation of a single step in a stepper motor does not affect the accuracy of the next step, so the accuracy of a stepper motor does not accumulate.

- Question:Question: What is the allowable surface temperature of the stepper motor?

- Answer:Answer: If the temperature of the stepper motor is too high, the magnetic material inside the motor may become demagnetized, resulting in a decrease or even loss of torque. Therefore, the maximum allowable surface temperature of the motor should depend on the demagnetization point of the magnetic material used in the motor; generally, the demagnetization point of magnetic materials is above 130°C, so a surface temperature of around 80°C for a stepper motor is completely normal.

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy