(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

- [Thông báo] Sử Dụng Địa Chỉ Hành Chính Mới Cho Giao/Nhận Hàng Hóa Từ 1/10/2025. Xem chi tiết.

[Notice] Update of Official Address for Delivery and Receipt of Goods from October 1, 2025. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng - Yêu Cầu Trả Phí Ship. Xem chi tiết

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more

Rail Length L

Assembly Height H

Nominal Part Number

Block Material (Surface Treatment)

Rail Material (Surface Treatment)

Rail Surface Treatment

CAD

Days to Ship

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Rail Length L(mm)

-

Assembly Height H(mm)

-

Nominal Part Number

-

Block Material (Surface Treatment)

- Carbon Steel (Bearing Steel)

- Stainless Steel

-

Rail Material (Surface Treatment)

- Carbon Steel (Bearing Steel)

- Stainless Steel

-

Rail Surface Treatment

- Vacuum evaporated chrome plating

- none

-

CADCAD

- 2D

- 3D

Days to ShipSố ngày giao hàng

-

- Alltất cả các

- 5 Day(s) or Less

- 12 Day(s) or Less

Specify AlterationsChỉ định thay đổi

Miniature Linear Guides Wide Rails

You can add up to 6 items per a category to the compare list.

Brand :

MiSUMi Economy

Part Number :

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

(i)

Caution

thận trọng

- **RoHS Compliant is available for some part numbers.

Please contact with MISUMI for detail effective date.

Seri E-MLG is discontinued, seri E-GMLG have surface treatment, seri E-SMLG have material is SUS - Alteration MC and Z1 may take longer leadtime, please contact machinery_bd@misumi.com.vn for more details

Product Description

Miniature Linear Guides Wide Rails

These linear guides or linear slides are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Rail Length Minimum/Maximum (mm.): 50 and 670

● Assembly Height (mm.): 9, 12, 14 and 16

● Rail Type : Wide Rail

● Option: Set (Rail + Block) / Block only

● Material: Rail- Bearing steel, Block - SUS440C

[Application]

It is used in a variety of machines such as CNC machines, 3D printers, measuring instruments, and so on.

See more ...

These linear guides or linear slides are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Rail Length Minimum/Maximum (mm.): 50 and 670

● Assembly Height (mm.): 9, 12, 14 and 16

● Rail Type : Wide Rail

● Option: Set (Rail + Block) / Block only

● Material: Rail- Bearing steel, Block - SUS440C

[Application]

It is used in a variety of machines such as CNC machines, 3D printers, measuring instruments, and so on.

See more ...

Economy Miniature Wide Rail Linear Guide

DurabilityWide RailAffordable

- Rail lengths available in multiple options

- Multiple assembly heights available

- Available as a set or block only

- Constructed from Carbon Steel and Stainless Steel

- Affordable alternative to standard products

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Product Overview

Linear guides (also known as slide rails or linear slides) are designed for precise linear motion and are used in high-precision applications. They provide higher load capacity and motion accuracy than linear bearings of the same size. These guides use rolling elements (such as steel balls) instead of an intermediate medium, allowing for smooth, precise movement even under high load conditions. They are commonly used in equipment like CNC machines, robotics, and automated systems.Product Comparison

| MISUMI Standard Product SSEBWL9-100 | Economy Series E-GMLGW7-100 | |

| Material | Stainless Steel | Carbon Steel |

| Hardness | 56HRC up | 58HRC up |

| Basic Rated Load C (Dynamic) (kN) | 1.4 | 1.37 |

| Basic Rated Load Co (Static) (kN) | 2.2 | 2.06 |

| Static Allowable Moment MA/MB (N・m) | 7.8 | 7.14 |

| Static Allowable Moment MC (N・m) | 15.5 | 15.7 |

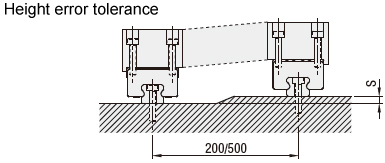

| Height H Tolerance Difference (μm) | ±20 | ±20 |

| Height H Pair Variation Difference (μm) | 15 | 40 |

| Width N Tolerance Difference (μm) | ±25 | ±25 |

| Width N Pair Variation Difference (μm) | 20 | 40 |

| Running Parallelism Guarantee (μm)* | 7 | 15 |

| Preload Management | Y | N |

| RoHS10 | Compliant | Compliant |

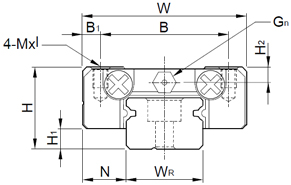

Dimensional Drawing

■ Material

| Type |  Material Material |  Rail Surface Treatment Rail Surface Treatment |  Hardness Hardness | Preload | |

| Guide Rail | Block | ||||

| E-MLGW | Bearing Steel | Stainless Steel | - | 58-62HRC | Z0 Ordinary Grade No Gap Type |

| E-GMLGW | Vacuum evaporated chrome plating | ||||

| E-SMLGW | Stainless Steel | - | 55-58HRC | ||

| E-SMLGWB | - | Stainless Steel | - | - | |

For vacuum chrome plating products(E-GMLGW), the cut surface on both ends is not treated.

For vacuum chrome plating products(E-GMLGW), the cut surface on both ends is not treated.Specification Table

■ Component kit

| Part Number |  Length L Length L(1mm increments) | Block Dimensions (mm) | Rail Dimension (mm) | |||||||||||||||||

Type Type |  Nominal Model Nominal Model | W | B | B1 | L1 | L2 | C | M×ℓ | H2 | Gn | H | H1 | N | HR | WR | WB | Counterbore d×D×h | P | E | |

| E-MLGW E-GMLGW E-SMLGW | 7 | 50~900 | 25 | 19 | 3 | 21 | 30.9 | 10 | M3×3 | 1.85 | Φ1.2 | 9 | 1.9 | 5.5 | 5.2 | 14 | - | 3.6×6×3.2 | 30 | Please refer to the calculation table below |

| 9 | 30 | 21 | 4.5 | 27.5 | 38.44 | 12 | 2.4 | 12 | 2.9 | 6 | 7 | 18 | 3.6×6×4.5 | |||||||

| 12 | 70~900 | 40 | 28 | 6 | 31.3 | 45.05 | 15 | M3×3.6 | 2.8 | 14 | 3.4 | 8 | 8.5 | 24 | 4.5×8×4.5 | 40 | ||||

| 15 | 60 | 45 | 7.5 | 38 | 54.19 | 20 | M4×4.2 | 3.2 | M3 | 16 | 9 | 9.5 | 42 | 23 | 4.5×8×4.5 | |||||

| Part Number | Block Dimensions (mm) | |||||||||

Type Type |  Nominal Model Nominal Model | W | B | B1 | L1 | L2 | C | Mxℓ | H2 | Gn |

| E-SMLGWB | 7 | 25 | 19 | 3 | 21 | 30.9 | 10 | M3×3 | 1.85 | Φ1.2 |

| 9 | 30 | 21 | 4.5 | 27.5 | 38.44 | 12 | 2.4 | |||

| 12 | 40 | 28 | 6 | 31.3 | 45.05 | 15 | M3×3.6 | 2.8 | ||

| 15 | 60 | 45 | 7.5 | 38 | 54.19 | 20 | M4×4.2 | 3.2 | M3 | |

The dimensional tolerance of L length is ±1mm and

The dimensional tolerance of L length is ±1mm and The dimensional tolerance of E end distance is ±0.5mm

The dimensional tolerance of E end distance is ±0.5mm■ L Detailed dimension of dimension specified type

Dimension L specified type cuts both ends of the rail equally. Refer to the table below for the number of mounting holes (M) of the slide rail at this time.

In addition, E dimension is calculated with the formula below.

L : Guide Rail length

M: Guide Rail mounting holes

P: Guide Rail holes pitch

Miniature Linear Guides Wide Rails -Standard rail-

| Nominal Model | 7 | 9 | 12 | 15 | Number of mounting holes M |

| L | 50~67 | 50~67 | 70~89 | 70~89 | 2 |

| 68~97 | 68~97 | 90~129 | 90~129 | 3 | |

| 98~127 | 98~127 | 130~169 | 130~169 | 4 | |

| 128~157 | 128~157 | 170~209 | 170~209 | 5 | |

| 158~187 | 158~187 | 210~249 | 210~249 | 6 | |

| 188~217 | 188~217 | 250~289 | 250~289 | 7 | |

| 218~247 | 218~247 | 290~329 | 290~329 | 8 | |

| 248~277 | 248~277 | 330~369 | 330~369 | 9 | |

| 278~307 | 278~307 | 370~409 | 370~409 | 10 | |

| 308~337 | 308~337 | 410~449 | 410~449 | 11 | |

| 338~367 | 338~367 | 450~489 | 450~489 | 12 | |

| 368~397 | 368~397 | 490~529 | 490~529 | 13 | |

| 398~427 | 398~427 | 530~569 | 530~569 | 14 | |

| 428~457 | 428~457 | 570~609 | 570~609 | 15 | |

| 458~487 | 458~487 | 610~649 | 610~649 | 16 | |

| P | 30 | 30 | 40 | 40 |

| Nominal Model | 7 | 9 | 12 | 15 | Number of mounting holes M |

| L | 488~517 | 488~517 | 650~689 | 650~689 | 17 |

| 518~547 | 518~547 | 690~729 | 690~729 | 18 | |

| 548~577 | 548~577 | 730~769 | 730~769 | 19 | |

| 578~607 | 578~607 | 770~809 | 770~809 | 20 | |

| 608~637 | 608~637 | 810~849 | 810~849 | 21 | |

| 638~667 | 638~667 | 850~889 | 850~889 | 22 | |

| 668~697 | 668~697 | 890~900 | 890~900 | 23 | |

| 698~727 | 698~727 | - | - | 24 | |

| 728~757 | 728~757 | 25 | |||

| 758~787 | 758~787 | 26 | |||

| 788~817 | 788~817 | 27 | |||

| 818~847 | 818~847 | 28 | |||

| 848~877 | 848~877 | 29 | |||

| 878~900 | 878~900 | 30 | |||

| P | 30 | 30 | 40 | 40 |

Alterations

| Alterations |  Code Code | Spec. | ||||||||

Change to Tapped Holes | MC | Ordering code: MC Change counterbored holes for fixing a guide to tapped holes.

| ||||||||

| 2-Block Specifications | B2 | 1 block added to 1-block product to ship as 2 block item. If the rail is too short to fit multiple blocks, the blocks will be shipped in a separate package. If the rail is too short to fit multiple blocks, the blocks will be shipped in a separate package. | ||||||||

| 3-Block Specifications | B3 | 2 blocks added to 1-block product to ship as 3 block item. If the rail is too short to fit multiple blocks, the blocks will be shipped in a separate package. If the rail is too short to fit multiple blocks, the blocks will be shipped in a separate package. | ||||||||

| 4-Block Specifications | B4 | 3 blocks added to 1-block product to ship as 4 block item. If the rail is too short to fit multiple blocks, the blocks will be shipped in a separate package. If the rail is too short to fit multiple blocks, the blocks will be shipped in a separate package. | ||||||||

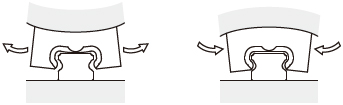

| Preload adjustment | ZF | Change Z0: zero preload to ZF: Normal clearance Z1: Light preload Z2: Medium preload | ||||||||

| Z1 | ||||||||||

| Z2 | ||||||||||

| Rail End Cut | Left End Cut ES | Specify the edge distance in 0.5 mm increments. When the specified edge distance exceeds or is close to the hole spacing, cutting may result in hole breakage. EB + ES = 2E. In cases where cutting is not feasible, distribute the dimensions evenly according to the standards. EB + ES = 2E. In cases where cutting is not feasible, distribute the dimensions evenly according to the standards. | ||||||||

| Right End Cut EB |

Precision Benchmark

●Dimensional Precision| Dimensional Precision Type | Precision Standard | Misumi |

| Miniature | Height H Tolerance | ±40 |

| Height H Pair Variation | 40 | |

| Width N Tolerance | ±40 | |

| Width N Pair Variation | 40 |

| Rail Length (mm) | Accuracy grade (μm) |

| Less than 50 | 12 |

| 50-80 | 13 |

| 80-125 | 15 |

| 125-200 | 15 |

| 200-250 | 16 |

| 250-315 | 17 |

| 315-400 | 18 |

| 400-500 | 19 |

| 500-630 | 20 |

| 630-800 | 22 |

| 800-900 | 23 |

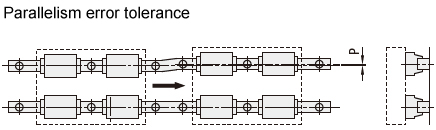

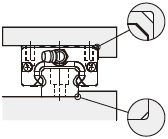

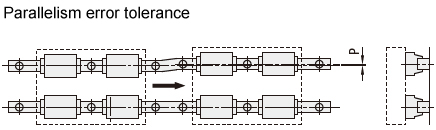

[Running Parallelism]

The values in the table are measured after the slide rail is fixed on the base.

When moving the slider within the entire length of the slide rail, measure the change of the upper surface C of the slider relative to the bottom surface A of the slide rail, and the change of the reference surface D of the slider relative to the reference surface B of the slide rail.

When moving the sliding block within the entire length of the slide rail, measure the change of the upper surface C of the slider relative to the bottom surface A of the slide rail, and the change of the reference surface D of the slider relative to the reference surface B of the slide rail.

Allowable Load

| Nominal Model | Basic Rated Load | Static Allowable Moment | Mass | |||

| C (Dynamic) kN | Co (Static) kN | MA・MB N-m | MC N-m | Blocks kg | Guide Rails kg/m | |

| 7 | 1.37 | 2.06 | 7.14 | 15.7 | 0.02 | 0.51 |

| 9 | 2.75 | 4.12 | 18.96 | 40.12 | 0.04 | 0.91 |

| 12 | 3.92 | 5.59 | 27.8 | 70.34 | 0.071 | 1.49 |

| 15 | 6.77 | 9.22 | 56.66 | 199.34 | 0.143 | 2.86 |

Product Features

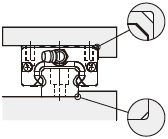

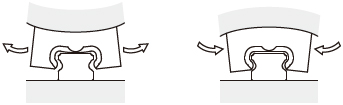

Feature 1: New construction, greatly reducing noise and improving smoothness.

Feature 2: The slide rail and the slider are in contact with each other through the rolling ball, so the shaking is small, and it is suitable for equipment with precision requirements.

Feature 3: Due to a point-to-surface contact, the frictional resistance is small, and it can perform subtle movements to achieve high precision positioning of the control device.

Feature 4: It has a large allowable load because the force on the rotating surface is dispersed due to the rolling groove of the ball.

Feature 5: It is suitable for high speed motion because it is not easy to produce friction heat when operating and not easily deformed by heat.

Feature 2: The slide rail and the slider are in contact with each other through the rolling ball, so the shaking is small, and it is suitable for equipment with precision requirements.

Feature 3: Due to a point-to-surface contact, the frictional resistance is small, and it can perform subtle movements to achieve high precision positioning of the control device.

Feature 4: It has a large allowable load because the force on the rotating surface is dispersed due to the rolling groove of the ball.

Feature 5: It is suitable for high speed motion because it is not easy to produce friction heat when operating and not easily deformed by heat.

Usage Method

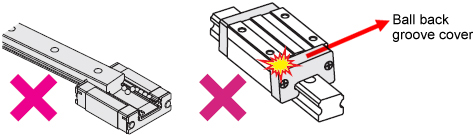

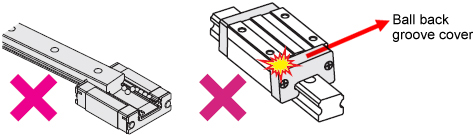

■ About use

① MISUMI's linear guide is installed with a retainer. Although the ball is not easy to fall off when the slide block is removed, the ball may fall off if the slider is removed from the rail at high speed, or tilted into the slide rail. Please disassemble the slider with care.

② Be sure to avoid colliding the ball back groove cover, otherwise it will affect the ball cycling, resulting in poor sliding.

③ If you have anti-rust requirements, please choose the Vacuum Chrome Plating Surface Treatment or Stainless Steel SUS440C products.

■ About maintenance (supply of grease)

① Grease forms an oil film on the surface of the linear guide ball and rail surface to effectively reduce friction and prevent sintering.

Decrease and aging of grease will greatly affect the life of the linear guide, so please add grease at the right time according to the service conditions.

MISUMI's linear guides are sealed with the greases listed below at the time of shipment, so they can be used directly.

② Recommend grease filling interval:

Usually every 6 months.

For longer moving distance, 3 months, or when the moving distance exceeds 1000km within the time limit, the 1000km shall prevail.

*The above is the grease injection interval under the moving distance standard. Depending on the operating environment, the grease injection interval must be shortened appropriately when the grease is aging and dirty.

① MISUMI's linear guide is installed with a retainer. Although the ball is not easy to fall off when the slide block is removed, the ball may fall off if the slider is removed from the rail at high speed, or tilted into the slide rail. Please disassemble the slider with care.

② Be sure to avoid colliding the ball back groove cover, otherwise it will affect the ball cycling, resulting in poor sliding.

③ If you have anti-rust requirements, please choose the Vacuum Chrome Plating Surface Treatment or Stainless Steel SUS440C products.

■ About maintenance (supply of grease)

① Grease forms an oil film on the surface of the linear guide ball and rail surface to effectively reduce friction and prevent sintering.

Decrease and aging of grease will greatly affect the life of the linear guide, so please add grease at the right time according to the service conditions.

MISUMI's linear guides are sealed with the greases listed below at the time of shipment, so they can be used directly.

② Recommend grease filling interval:

Usually every 6 months.

For longer moving distance, 3 months, or when the moving distance exceeds 1000km within the time limit, the 1000km shall prevail.

*The above is the grease injection interval under the moving distance standard. Depending on the operating environment, the grease injection interval must be shortened appropriately when the grease is aging and dirty.

Precautions

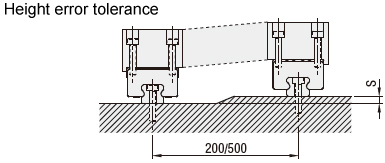

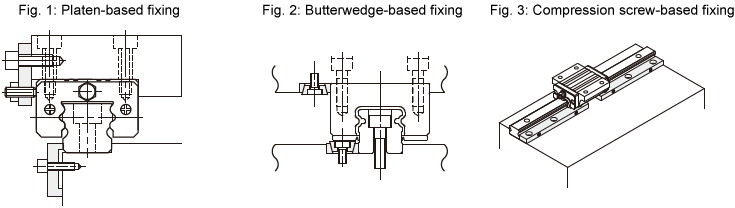

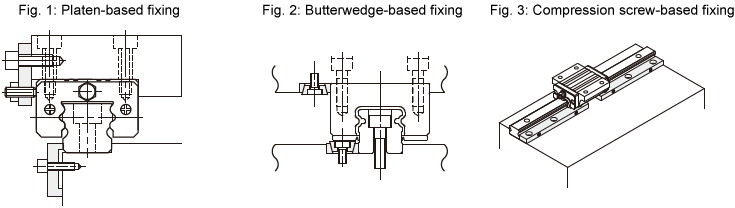

For normal use, the installation of the linear guide needs to meet the following four points:

① Whether the shape of the mounting surface produces interference

② Keep the flatness of the workpiece mounting surface at about 5μ, otherwise the slider will be slightly deformed

③ Whether the error values of guide parallelism and fitting height are within the allowable installation values

④ Use the standard

installation method Click here for the detailed installation method

here for the detailed installation method

② Keep the flatness of the workpiece mounting surface at about 5μ, otherwise the slider will be slightly deformed

③ Whether the error values of guide parallelism and fitting height are within the allowable installation values

④ Use the standard

installation method Click

here for the detailed installation method

here for the detailed installation methodExample of Use

Mechanism Name: 4 times stroke slide

Feature 1: suitable for medium frequency driving and positioning.

Feature 2: transfer the light workpiece on the worktable according to 4 times the distance of the cylinder stroke.

For details, click here

here

Feature 1: suitable for medium frequency driving and positioning.

Feature 2: transfer the light workpiece on the worktable according to 4 times the distance of the cylinder stroke.

For details, click

here

hereApplication Industries

| Medical | Smart phone | |

|  | |

| Robotics | Electronic & Electrical Appliances | |

|  |

Related Products

| Miniature Linear Guides | Medium Load linear guide | Heavy Load linear guide | ||

|  |  | ||

| Typical model: SSEBZ10-55 | Typical model: SVR24-280 | Typical model: SXR24-280 |

Related Documents

For the installation and use of linear guides, please refer to here

here

here

herePart Number

- Incomplete part number.

Please use left hand selections to complete a part number.Incomplete part number.

Please use left hand selections to complete a part number.

Loading...Tải…

| Part Number |

|---|

| E-GMLGW7-[42-900/1] |

| E-GMLGW9-[50-900/1] |

| E-GMLGW12-[60-900/1] |

| E-GMLGW15-[70-900/1] |

| E-SMLGW7-[50-900/1] |

| E-SMLGW9-[50-900/1] |

| E-SMLGW12-[70-900/1] |

| E-SMLGW15-[70-900/1] |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to ShipSố ngày giao hàng | Rail Length L (mm) | Assembly Height H (mm) | Nominal Part Number | Basic Load Rating: Dynamic Load (N) | Basic Load Rating: Static Load (R) | Allowable Static Moment MA (θ) | Allowable Static Moment MB (N) | Allowable Static Moment MC (N) | Block Material (Surface Treatment) | Rail Material (Surface Treatment) | Rail Surface Treatment |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | 12 Day(s) | 42 ~ 900 | 9 | 7 | 1.37 | 2.06 | 7.14 | 7.14 | 15.7 | Carbon Steel (Bearing Steel) | Carbon Steel (Bearing Steel) | Vacuum evaporated chrome plating | ||

- | 1 Piece(s) | 12 Day(s) | 50 ~ 900 | 12 | 9 | 2.75 | 4.12 | 18.96 | 18.96 | 40.12 | Carbon Steel (Bearing Steel) | Carbon Steel (Bearing Steel) | Vacuum evaporated chrome plating | ||

- | 1 Piece(s) | 12 Day(s) | 60 ~ 900 | 14 | 12 | 3.92 | 5.59 | 27.8 | 27.8 | 70.34 | Carbon Steel (Bearing Steel) | Carbon Steel (Bearing Steel) | Vacuum evaporated chrome plating | ||

- | 1 Piece(s) | 12 Day(s) | 70 ~ 900 | 16 | 15 | 6.77 | 9.22 | 56.66 | 56.66 | 199.34 | Carbon Steel (Bearing Steel) | Carbon Steel (Bearing Steel) | Vacuum evaporated chrome plating | ||

- | 1 Piece(s) | 5 Day(s) | 50 ~ 900 | 9 | 7 | 1.37 | 2.06 | 7.14 | 7.14 | 15.7 | Stainless Steel | Stainless Steel | none | ||

- | 1 Piece(s) | 5 Day(s) | 50 ~ 900 | 12 | 9 | 2.75 | 4.12 | 18.96 | 18.96 | 40.12 | Stainless Steel | Stainless Steel | none | ||

- | 1 Piece(s) | 5 Day(s) | 70 ~ 900 | 14 | 12 | 3.92 | 5.59 | 27.8 | 27.8 | 70.34 | Stainless Steel | Stainless Steel | none | ||

- | 1 Piece(s) | 5 Day(s) | 70 ~ 900 | 16 | 15 | 6.77 | 9.22 | 56.66 | 56.66 | 199.34 | Stainless Steel | Stainless Steel | none |

Loading...Tải…

Basic InformationThông tin cơ bản

| Block Type(mm) | Standard Block | Rail Type | Wide Rail | Set / Single Item | Set |

|---|---|---|---|---|---|

| Preload(N・m) | Normal Clearance | Accuracy Standards(N・m) | Standard Grade | Material | Stainless Steel |

| Ball Arrangement | Miniature Type | No. of Blocks(mm) | 1 | Retainer | N/A |

| Lubrication Type(mm) | Lubrication Applied | Rolling Element | Ball | Lubrication Type | Lithium Grease Filled |

| L Dimension Type | Specified Type |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer toCác thông số kỹ thuật và kích thước của mã sản phẩm có thể không được bao phủ đầy đủ. Để biết chi tiết chính xác, hãy tham khảo manufacturer catalogsdanh mục nhà sản xuất ..

Frequently asked question (FAQ)FAQ

- Question:Question: Can linear guides or sliders be purchased separately?

- Answer:Answer: Taking into account the accuracy of products, single slider models clearly indicated in the catalog can be purchased, and no others can be purchased.

- Question:Question: Can the stainless steel guide rails be guaranteed not to rust?

- Answer:Answer: Stainless steel is a product that has a certain antirust function compared to carbon steel, but it cannot be guaranteed that it will never rust. Depending on the operating environment, there may also be short-term rust.

- Question:Question: What problems should be paid attention to when the linear guide is installed vertically?

- Answer:Answer: Attention should be paid to prevent the slider from falling off and causing the balls to fall off during installation.

- Question:Question: What does micro preloading in linear guide mean?

- Answer:Answer: MISUMI's linear guides control the clearance by selecting the size of the internal ball. Through the negative clearance, the rigidity is improved and the elastic displacement is reduced. This is preloading. Generally speaking, the life and accuracy of the micro preloading type will be better than that of the standard clearance type.

- Question:Question: Linear guide indicators include basic dynamic load rating and basic static load rating. Which indicator is the reference when selecting?

- Answer:Answer: The basic dynamic load rating is used to calculate the rail life, and the basic static load rating is used to calculate the maximum allowable load.

- Question:Question: Can the corresponding linear guide products be selected according to the third-party guide rail model?

- Answer:Answer: MISUMI offers third-party brand replacement services, so as long as the third party product model is given, we can replace it with corresponding MISUMI model. For details, please contact the customer service email or call the customer service phone.

- Question:Question: Can the rail or slider be repaired if it is damaged?

- Answer:Answer: Repair service is not provided, re-purchase is recommended.

- Question:Question: Can linear guide length be arbitrarily specified?

- Answer:Answer: It can be specified arbitrarily. However, MISUMI linear guides are divided into length fixed type and length specified type, and in case of length specified type, the length dimensions for length fixed type cannot be specified.

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy